Materials

Materials necessary for the production of assembly insoles, cleaning insoles and fussbett insoles for men’s, women’s and children’s footwear, safety and work shoes.

1) MICROCELLULAR POLYESTER-BASED POLYURETHANE SYSTEM

Used for the production of fussbett in the footwear industry with casting or injection technology.

Thanks to the characteristics of polyurethane, the polyol + isocyanate system satisfies the requirements of lightness, comfort, resistance to abrasion.

– packages: tanks.

2) CELLULOSIC CARDBOARD

Cellulosic cardboard in printed sheets for insoles with specified cutting direction.

– formulated with 100% recyclable waste;

– standard sheet size: 1000×1500 mm;

– non-standard sheet size: avaible on request;

– standard thicknesses: 0,80 mm – 0,90 mm – 1,25 mm – 1,50 mm – 1,75 mm – 2,00 mm.

3) FIBER CARDBOARD for footwear use for half insoles of brown color.

Size: 106×156 cm;

Thicknesses: from 0,8 mm to 3mm.

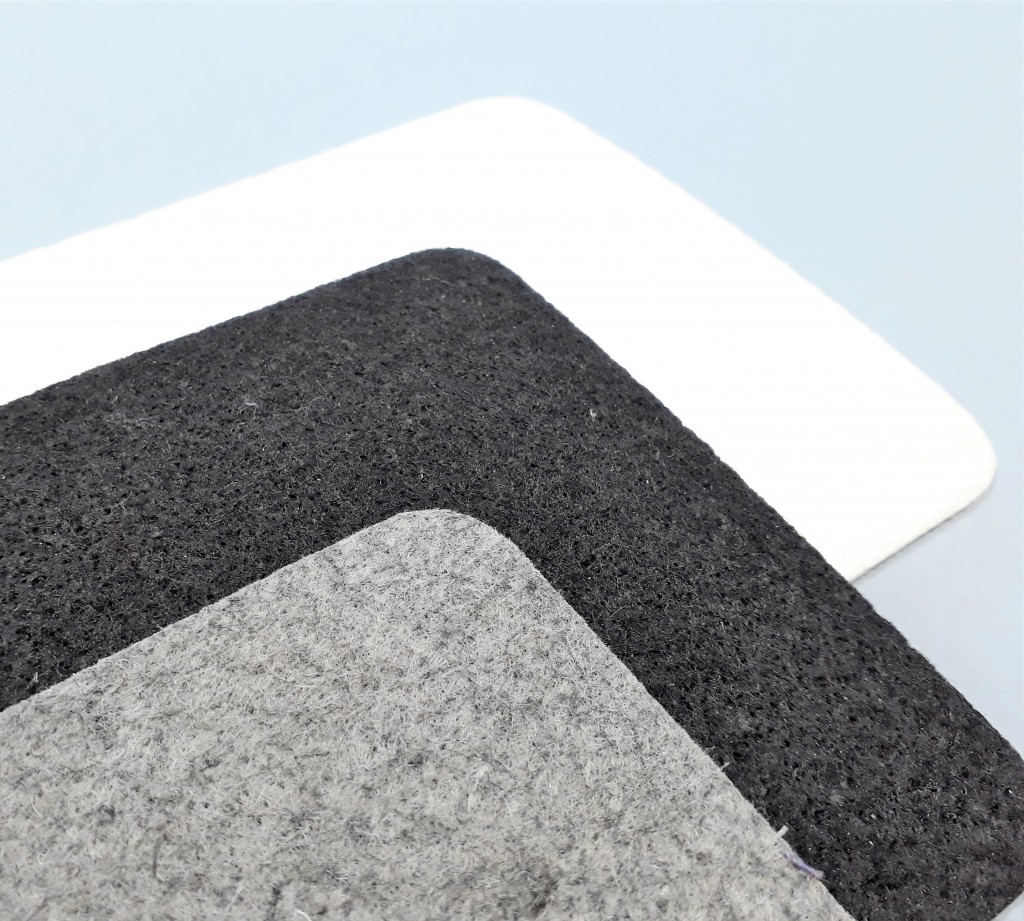

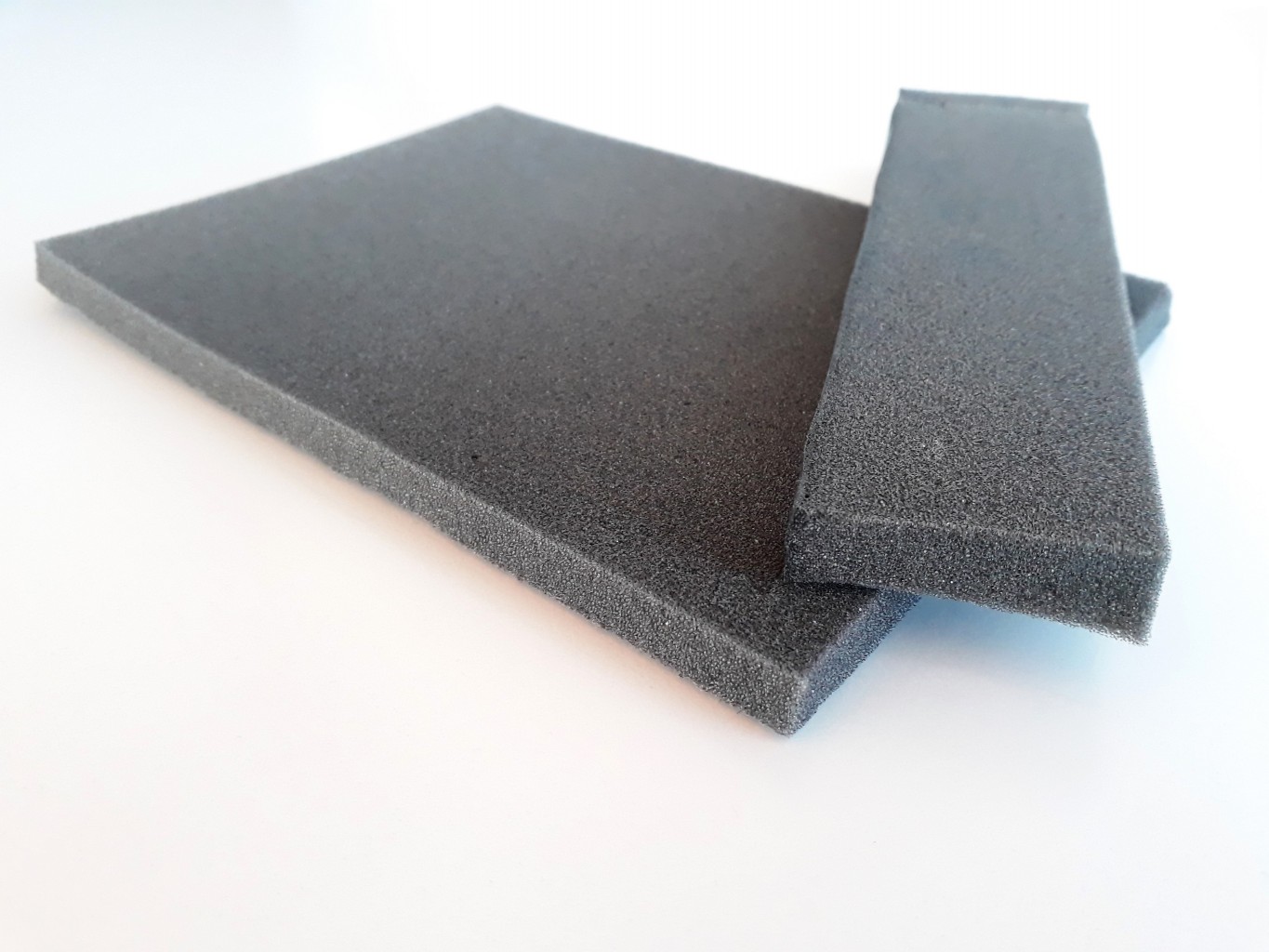

4) FOAM, GEL, FOAM RUBBER AND SYNTHETIC LATEX

Coupled or coated on diffrent supports for insoles. They can be: breathable, elastic, with antibacterial treatment, memory. Different degrees of density. Various colors and thicknesses on request.

– package: rolls or sheets.

5) STROBEL MATERIAL

Non-woven fabric made of synthetic fibers with a polypropylene reinforcement and impregnated with synthetic resins in water dispersion. It is used in the footwear industry for the production of insoles using the strobel sewing.

Characteristics:

– various colors and thicknesses on request;

– good tensile strength;

– dimensional stability;

– resistance to the stitching point;

– package: rolls.